Industry knowledge

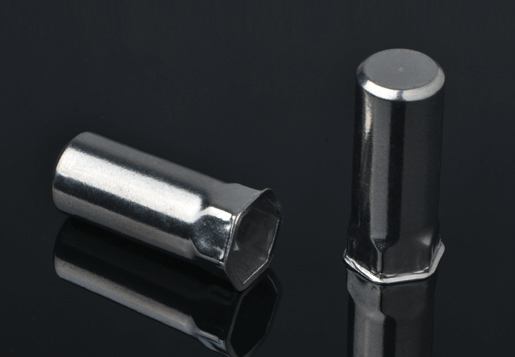

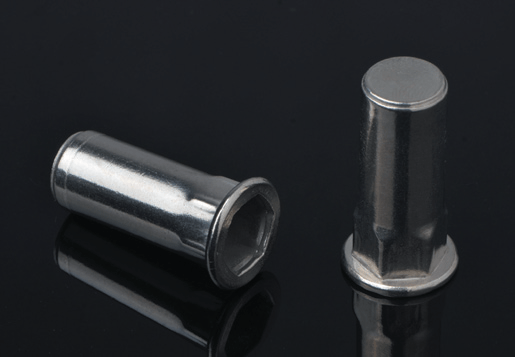

What is UT Unthreaded Stud?

A UT unthreaded stud typically refers to an unthreaded metal rod or bolt used for various applications, particularly in construction, manufacturing, and engineering. "UT" stands for "unified thread," which is a standardized thread form used for fastening purposes.

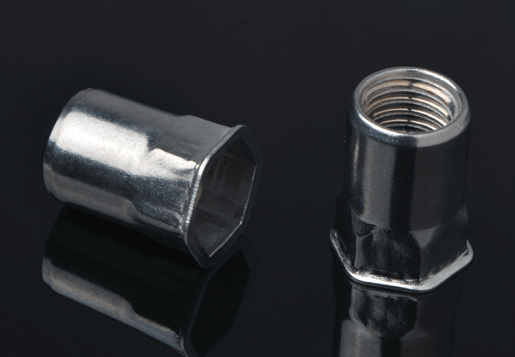

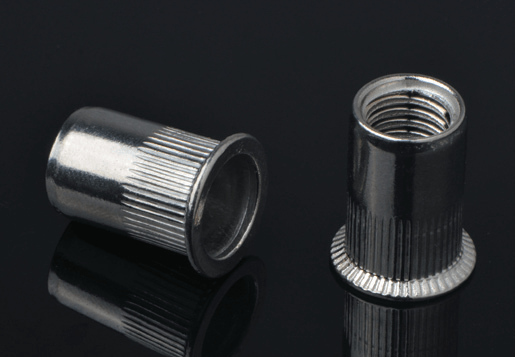

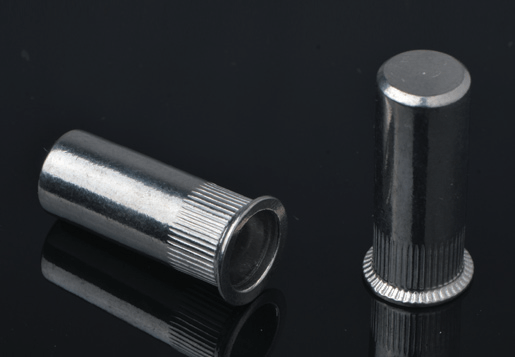

Unlike threaded studs that have helical grooves along their length, unthreaded studs do not have any threads. Instead, they feature a smooth, cylindrical surface from end to end. Unthreaded studs are commonly used in scenarios where the fastening element needs to be inserted into a pre-drilled hole and secured with a nut or other fastening component.

The absence of threads on UT unthreaded studs allows for a flush, streamlined appearance once installed. They offer advantages such as ease of installation, versatility, and the ability to disassemble and reassemble components quickly.

UT unthreaded studs are available in various materials, including steel, stainless steel, aluminum, and brass, depending on the specific application requirements. They come in different diameters, lengths, and head configurations to accommodate different load capacities and installation methods.

Overall, UT unthreaded studs play a vital role in joining components together securely, providing stability, strength, and flexibility in various industries.

UT unthreaded studs offer several benefits in various applications. Here are some of the advantages:

Versatility: Unthreaded studs provide versatility in fastening applications. They can be used in a wide range of industries, including construction, automotive, aerospace, electronics, and more. Their ability to accommodate different sizes, materials, and configurations makes them suitable for diverse projects.

Easy Installation: Installing UT unthreaded studs is generally straightforward. They are inserted into pre-drilled holes, eliminating the need for threading or tapping. This simplifies the installation process and reduces assembly time, especially when compared to threaded studs.

Adjustable Length: Unthreaded studs allow for flexibility in terms of length adjustment. By cutting the stud to the desired size, it can be customized to fit specific requirements. This adjustability makes them suitable for applications where the depth of penetration needs to be controlled precisely.

Secure Fastening: When combined with nuts, washers, or other fastening components, UT unthreaded studs offer reliable and secure fastening. The absence of threads along the stud's length ensures a flush and smooth connection, minimizing the risk of loosening or stripping.

Reusability: Unthreaded studs can be easily disassembled and reassembled without damaging the threads, as there are no threads to wear down. This feature allows for component replacement, maintenance, or adjustments without the need for complete stud replacement.

Aesthetics: UT unthreaded studs provide a clean and streamlined appearance. Their smooth, unthreaded surface gives a professional finish, which is desired in applications where aesthetics are important, such as in architectural or decorative projects.

Cost-Effective: Unthreaded studs are often more cost-effective than threaded studs. Their simpler manufacturing process and the absence of threads contribute to lower production costs. Additionally, their ease of installation and reusability can lead to time and cost savings during assembly, disassembly, and maintenance procedures.

EN

EN  英语

英语 俄语

俄语 韩语

韩语 阿拉伯语

阿拉伯语 土耳其语

土耳其语

+(86)-133 8863 9264

+(86)-133 8863 9264