Industry knowledge

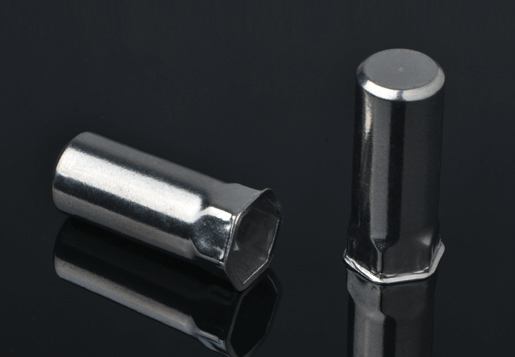

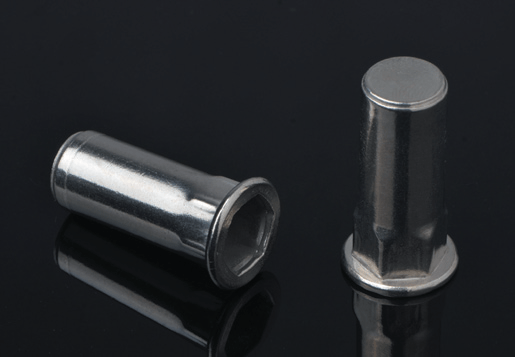

What is Threaded Studs?

Threaded studs are fasteners that consist of a long metal rod with threads on one end and a plain shank on the other. They are commonly used in construction, manufacturing, and various other industries where a secure and removable connection is required.

The threaded end of a stud is designed to be screwed into a pre-drilled or pre-tapped hole, providing a reliable connection between two objects. The threads on the stud can be of various types, such as coarse or fine threads, depending on the specific application and requirements.

Threaded studs are often made from materials like steel, stainless steel, or brass, which offer strength, durability, and corrosion resistance. They come in various lengths, diameters, and thread sizes to accommodate different needs.

One common application of threaded studs is in welding. They are often welded to a metal surface, providing a threaded connection point for attaching other components or structures. Threaded studs are also used in electrical grounding applications, where they provide a secure point for connecting wires or grounding equipment.

Overall, threaded studs are versatile fasteners that offer a reliable and removable connection in a wide range of industries and applications.

The Application of Threaded Studs

Threaded studs have a wide range of applications in various industries. Here are some common uses of threaded studs:

Construction:

Threaded studs are used in construction projects for fastening structural components together. They are commonly used in steel framing, concrete formwork, and other applications where a strong and reliable connection is required.

Manufacturing: Threaded studs find extensive use in manufacturing industries. They are used for assembling machinery, equipment, and fixtures. Threaded studs can be welded, screwed, or pressed into place to provide a secure attachment point for other components.

Electrical and Electronics: Threaded studs are utilized in electrical and electronics applications for grounding and bonding purposes. They provide a threaded connection point for attaching electrical wires, grounding terminals, and other electrical components.

Automotive: In the automotive industry, threaded studs are employed for securing various parts and components. They are used in engine assemblies, suspension systems, body panels, and other areas where a strong and removable connection is needed.

Plumbing and HVAC: Threaded studs are used in plumbing and HVAC (Heating, Ventilation, and Air Conditioning) systems. They are used to connect pipes, fittings, and equipment securely, ensuring leak-free installations.

Furniture and Cabinetry: Threaded studs are used in furniture and cabinetry manufacturing for joining components together. They provide a strong connection between parts such as table legs, chair frames, and cabinet sections.

Marine and Aerospace: Threaded studs are used in marine and aerospace applications where high-strength fastening is critical. They are used in the assembly of ship structures, aircraft components, and other marine or aerospace equipment.

Maintenance and Repair: Threaded studs are often used in maintenance and repair work across various industries. They can be used to replace damaged or worn-out fasteners, providing a quick and reliable solution.

These are just a few examples of the many applications of threaded studs. Their versatility, strength, and ease of installation make them a popular choice in numerous industries where secure and removable connections are essential.

EN

EN  英语

英语 俄语

俄语 韩语

韩语 阿拉伯语

阿拉伯语 土耳其语

土耳其语

+(86)-133 8863 9264

+(86)-133 8863 9264