STEADY manufactures over a thousands different types of blind rivet nut in steel,aluminium and stainless steel,thread size from M3-M16 in metric and UNC #6-32 to UNC 1/2-13 in inch. High advantage in stainless steel blind rivets both for open and sealed type, mutigrip,monobolt and other structural rivets. As China Tension Control Shear Bolts Manufacturers and Tension Control Shear Bolts Factory, we focus on "one stop shopping" and with advantage of large production capacity , consistent quality, competitive prices, punctual delivery and goods serverices before and after sales, STEADY has become one of the leading blind fasteners manufacuture & supplier in Asia.

Tension Control Shear Bolts Manufacturers

-- Steady & Reliable Manufacturer --

Introduction

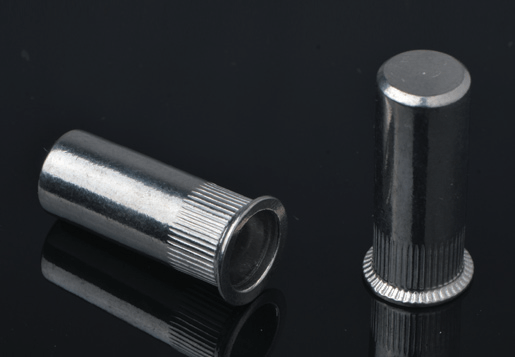

Tension Control (TC) Shear Bolts, commonly used in structural steel construction, are designed for guaranteed, consistent pre-load application. The system consists of a round head bolt, a nut, and a washer, all tightened using a specialized electric shear wrench. The bolt's splined end shears off when the precise tension is reached, providing a visual and mechanical confirmation that the joint has achieved the required clamping force, ensuring safety and compliance on critical construction projects.

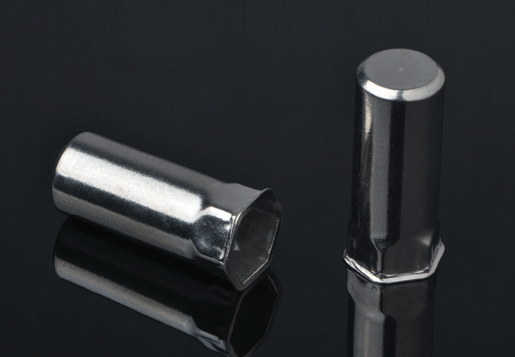

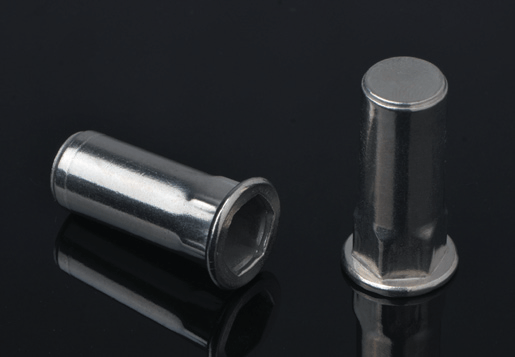

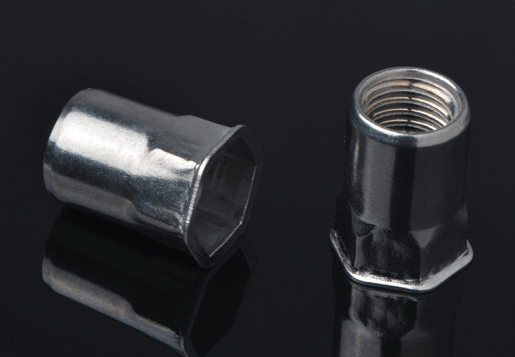

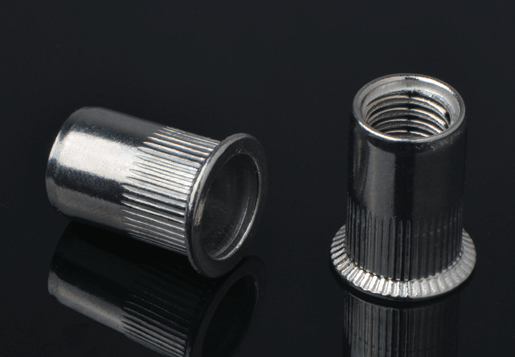

Related products

Specification

| Type |

Tension Control (TC) Bolt Assembly |

| Standard |

ASTM F1852 / F2280 Equivalent (often HDG or plain) |

| Components |

Bolt (splined end) + Nut + Washer |

| Installation |

Electric Shear Wrench (one-tool system) |

| Key Feature |

Visual Confirmation of Pre-load |

Applications

-

High-Rise Construction: Used for quick and reliable joining of structural steel members.

-

Bridge Girders: Essential for critical load-bearing joints in bridge assembly.

-

Seismic Zones: Preferred in areas requiring highly consistent and traceable bolt tensioning.

-

Industrial Facilities: Used in large, prefabricated steel structures.

Advantages

-

Guaranteed Tension: The shearing action ensures the precise tension is achieved every time, regardless of installer skill.

-

Speed of Installation: One worker can install TC bolts rapidly using a single specialized tool.

-

Improved Safety: Eliminates the need for traditional turn-of-nut or torque calibration methods, simplifying inspection.

-

Reduced Inspection Costs: Inspection merely requires verifying the spline has sheared off.

EN

EN  English

English русский

русский 한국어

한국어 عربى

عربى Türk

Türk