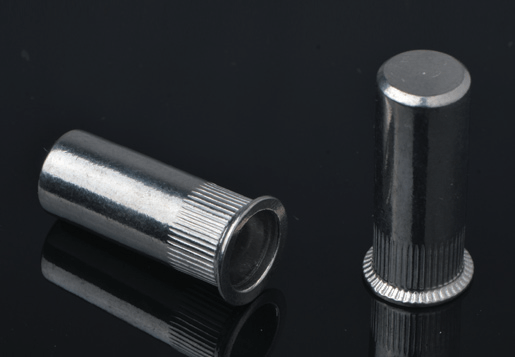

STEADY manufactures over a thousands different types of blind rivet nut in steel,aluminium and stainless steel,thread size from M3-M16 in metric and UNC #6-32 to UNC 1/2-13 in inch. High advantage in stainless steel blind rivets both for open and sealed type, mutigrip,monobolt and other structural rivets. As China High Strength Wind Turbine Bolts Manufacturers and High Strength Wind Turbine Bolts Factory, we focus on "one stop shopping" and with advantage of large production capacity , consistent quality, competitive prices, punctual delivery and goods serverices before and after sales, STEADY has become one of the leading blind fasteners manufacuture & supplier in Asia.

High Strength Wind Turbine Bolts Manufacturers

-- Steady & Reliable Manufacturer --

Introduction

Fasteners for wind turbines are among the most critical and highly engineered in the industrial world, requiring exceptional strength, fatigue resistance, and absolute reliability. Our High Strength Wind Turbine Bolts (typically Class 10.9 and 12.9) are manufactured under strict control to connect massive tower sections, hubs, and blades, enduring massive dynamic loads and extreme weather conditions. Full material traceability and non-destructive testing are standard requirements for all wind energy fasteners we supply.

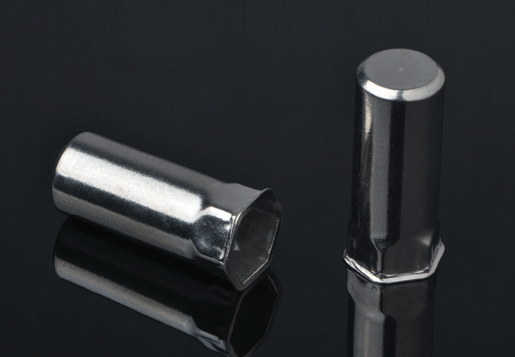

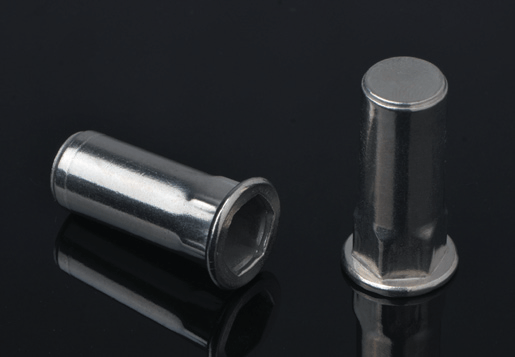

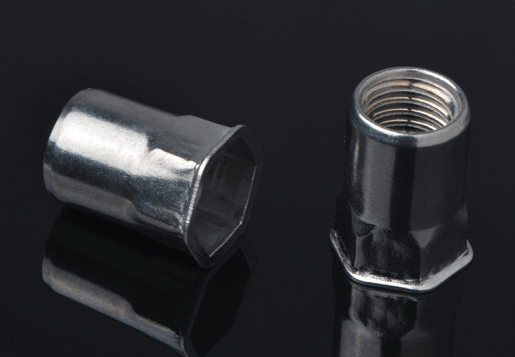

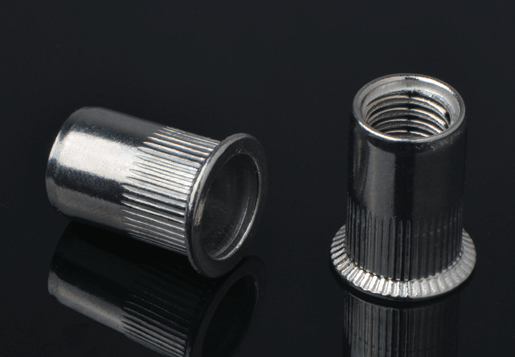

Related products

Specification

| Property Class |

10.9, 12.9 (Heavy Hex Configuration) |

| Diameter Range |

M24 to M72 (Large Diameter) |

| Coating System |

Zinc Flake (Geomet/Dacromet), Hot Dip Galvanized (Special) |

| Testing Required |

Magnetic Particle Inspection (MPI), Ultrasonic Testing (UT) |

| Key Feature |

High Fatigue Resistance |

Applications

-

Tower Segment Flanges: Connecting large sections of the turbine tower.

-

Rotor Hub Assembly: Fastening the massive rotor hub to the gearbox and main shaft.

-

Foundation Anchoring: Securing the turbine base to the concrete foundation.

-

Yaw and Pitch Systems: Used in the mechanical systems that rotate the nacelle and adjust the blades.

Advantages

-

Critical Load Capacity: Designed for high pre-load and maximum resistance to fatigue failure.

-

Full Traceability: Complete documentation from raw material to final shipment, essential for liability and safety.

-

Specialized Coatings: Coatings optimized for long-term corrosion protection in high-vibration, dynamic environments.

-

Reduced Downtime: Reliable quality means fewer failures and lower maintenance costs over the turbine's lifespan.

EN

EN  English

English русский

русский 한국어

한국어 عربى

عربى Türk

Türk