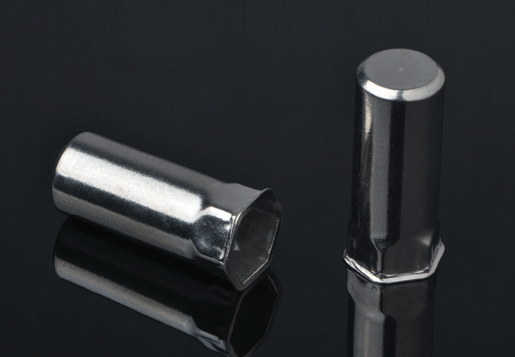

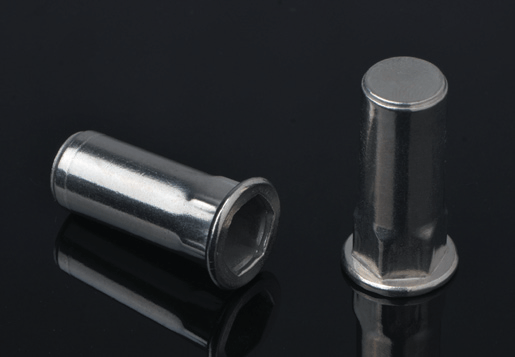

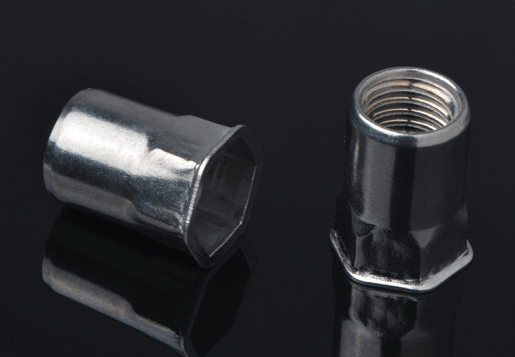

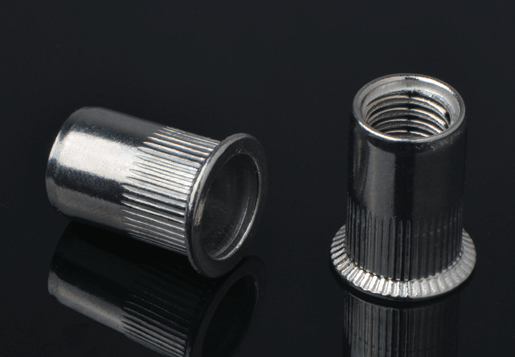

STEADY manufactures over a thousands different types of blind rivet nut in steel,aluminium and stainless steel,thread size from M3-M16 in metric and UNC #6-32 to UNC 1/2-13 in inch. High advantage in stainless steel blind rivets both for open and sealed type, mutigrip,monobolt and other structural rivets. As China High Tensile Structural Bolts 10.9 Manufacturers and High Tensile Structural Bolts 10.9 Factory, we focus on "one stop shopping" and with advantage of large production capacity , consistent quality, competitive prices, punctual delivery and goods serverices before and after sales, STEADY has become one of the leading blind fasteners manufacuture & supplier in Asia.

High Tensile Structural Bolts 10.9 Manufacturers

-- Steady & Reliable Manufacturer --

Introduction

Class 10.9 structural bolts are high-strength fasteners engineered for heavy-duty load-bearing applications in construction and mechanical industries. With a minimum tensile strength of 1040 MPa, these bolts provide the required clamping force and shear resistance critical for structural steel connections where safety and stability are paramount. We ensure every batch is rigorously tested to meet or exceed international standards like ISO 898-1.

Related products

Specification

| Property Class |

10.9 |

| Tensile Strength (min) |

1040 MPa |

| Yield Strength (min) |

940 MPa |

| Material |

Medium Carbon Steel, Quenched and Tempered |

| Standard |

ISO 898-1, DIN 931/933 Equivalent |

Applications

-

Structural Steel Framing: Essential for building high-rise towers and large industrial facilities.

-

Heavy Machinery Assembly: Securing major components in excavators, cranes, and mining equipment.

-

Bridges and Overpasses: Used in critical joints where high pre-load and fatigue resistance are required.

-

Renewable Energy Systems: Found in the foundation and tower sections of wind turbines.

Advantages

-

Exceptional Strength: Provides significantly higher clamping force than standard 8.8 bolts, allowing for smaller joint size or fewer fasteners.

-

Fatigue Resistance: Engineered to withstand cyclic loading typical in dynamic structures.

-

Traceability: Each batch is supplied with Material Test Reports (MTRs) certifying compliance with mechanical properties.

-

Dimensional Accuracy: Precision forging ensures optimal fit with compatible nuts and washers.

EN

EN  English

English русский

русский 한국어

한국어 عربى

عربى Türk

Türk