Industry knowledge

What is PT Threaded Stud?

A

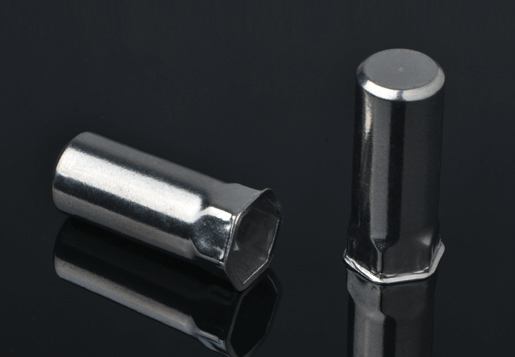

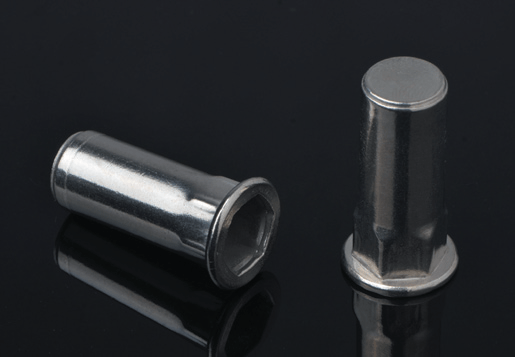

PT threaded stud refers to a type of fastener used in various applications. "PT" stands for "Pipe Thread," indicating that the stud has threads compatible with pipe fittings.

A threaded stud typically consists of a cylindrical rod with external threads on one end and a plain shank on the other. The threaded end allows the stud to be screwed into a threaded hole or fitting, while the shank provides stability and support. The threads on a PT threaded stud follow standard pipe thread specifications, such as NPT (National Pipe Thread) or BSP (British Standard Pipe).

These studs are commonly used in plumbing, piping systems, and other applications where a secure and leak-free connection is required. They are often used to connect pipes, fittings, valves, or other components together. The threads on the stud ensure a tight seal when properly tightened with compatible fittings, preventing leakage of fluids or gases.

It's important to note that while PT threaded studs are designed for pipe thread connections, they are not limited to use in plumbing alone. They can be used in various industries and applications where pipe threads are employed, such as hydraulic systems, pneumatic systems, and certain types of machinery.

When using PT threaded studs, it is essential to match the thread specifications (e.g., NPT or BSP) to ensure compatibility with the corresponding fittings and components.

PT threaded studs play a crucial role in various applications due to the following reasons:

Secure Connections: PT threaded studs provide a reliable and secure connection between pipes, fittings, valves, or other components. The threaded design allows for a tight and leak-free joint when properly installed and tightened with compatible fittings. This is particularly important in plumbing and piping systems where maintaining fluid or gas integrity is critical.

Versatility: PT threaded studs can be used in a wide range of applications, including plumbing, hydraulic systems, pneumatic systems, and machinery. Their compatibility with standard pipe thread specifications (such as NPT or BSP) allows for their use in different industries and sectors.

Ease of Installation: The threaded design of PT studs simplifies the installation process. They can be easily screwed into threaded holes or fittings, requiring minimal tools or equipment. This ease of installation can save time and effort during assembly or repairs.

Adjustable Length: PT threaded studs often come in various lengths, allowing for customization based on specific requirements. This adjustability makes them suitable for installations that involve varying distances between components or where the length of the stud needs to be modified to achieve the desired connection.

Durability: PT threaded studs are typically made from robust and durable materials, such as steel or stainless steel, ensuring their longevity and ability to withstand harsh operating conditions. This durability is crucial in applications that involve high pressures, temperature fluctuations, or exposure to corrosive environments.

Standardization: The use of standard pipe thread specifications for PT studs promotes compatibility and interchangeability across different systems and industries. This standardization simplifies sourcing, maintenance, and repairs, as compatible fittings and components are readily available.

Overall, PT threaded studs are important because they provide a secure, leak-free, and versatile connection solution in various applications. Their ease of installation, durability, and compatibility with standard pipe thread specifications make them a reliable choice for joining components in plumbing, piping, and other systems.

EN

EN  英语

英语 俄语

俄语 韩语

韩语 阿拉伯语

阿拉伯语 土耳其语

土耳其语

+(86)-133 8863 9264

+(86)-133 8863 9264