Industry knowledge

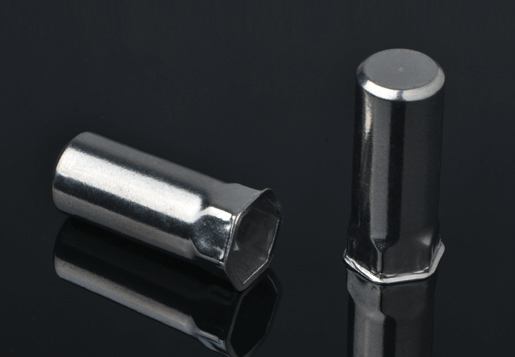

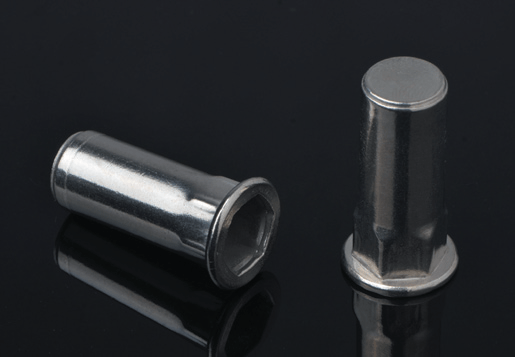

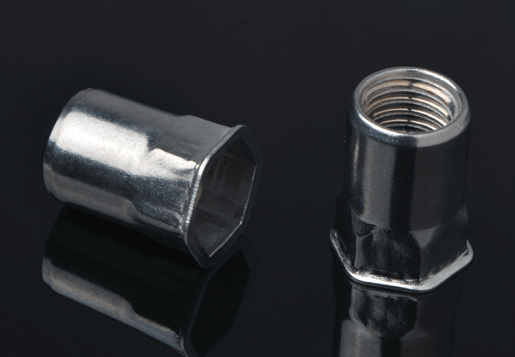

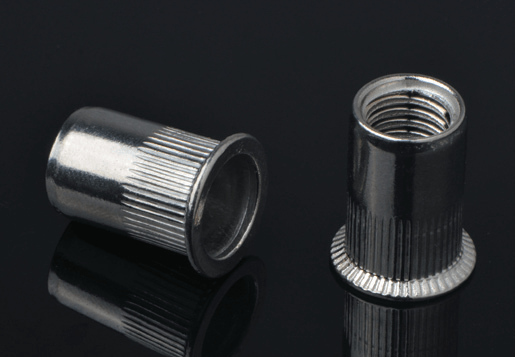

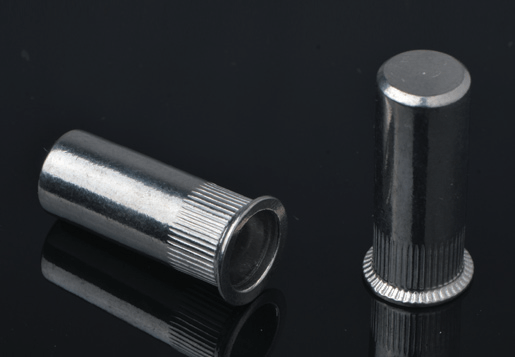

A "stud with internal thread" typically refers to a type of fastening component or threaded rod that has threads on the inside rather than the outside. It is designed to be used in conjunction with a corresponding externally threaded component, such as a bolt or screw.

Unlike a traditional bolt or screw, which has external threads that engage with the internal threads of a nut or tapped hole, a stud with internal thread allows for a different type of fastening arrangement. It can be inserted into a pre-drilled or pre-tapped hole and secured by tightening a nut onto its external threads. This creates a strong and secure connection between the two components.

Studs with internal threads are commonly used in various applications, including machinery, construction, automotive, and engineering projects. They offer advantages such as simplified assembly, the ability to easily disassemble and reassemble components, and increased flexibility in design and alignment.

The Benefits of Stud With Internal Thread

Studs with internal threads offer several benefits in various applications. Here are some of the advantages:

Enhanced Assembly: Studs with internal threads simplify the assembly process. They can be easily inserted into pre-drilled or pre-tapped holes without the need for additional tools or operations. This speeds up the assembly time and reduces labor requirements.

Improved Strength: Compared to conventional threaded fasteners, such as bolts or screws, studs with internal threads can provide increased strength and stability. The engagement of the internal threads with a nut creates a more secure and robust connection, reducing the risk of loosening or failure under load or vibration.

Disassembly and Reassembly: One significant advantage of studs with internal threads is their ability to facilitate easy disassembly and reassembly. Instead of unthreading a bolt or screw from a component, the nut can be simply loosened or removed, allowing for quick and convenient separation of the connected parts. This feature is particularly beneficial in maintenance, repair, and reconfiguration scenarios.

Alignment and Positioning:

Studs with internal threads help in achieving precise alignment and positioning of components during assembly. Since the stud is inserted into a pre-drilled or pre-tapped hole, it ensures accurate placement of the connected parts. This is especially useful in applications where alignment is critical, such as in machinery or structural installations.

Flexibility in Design: The use of studs with internal threads provides greater flexibility in design and component selection. It allows for the use of thinner or more lightweight materials since the internal threads can be incorporated into the stud itself, rather than requiring external threads on the component. This flexibility can lead to more efficient designs and cost savings.

Thread Protection: The internal threads of a stud with internal thread are protected from external contaminants, such as dirt, dust, or corrosion. This can contribute to the longevity and reliability of the fastening system, particularly in demanding or harsh environments.

Overall, studs with internal threads offer advantages in terms of assembly efficiency, strength, disassembly convenience, alignment accuracy, design flexibility, and thread protection. These benefits make them a popular choice in various industries where secure and reliable fastening is required.

EN

EN  英语

英语 俄语

俄语 韩语

韩语 阿拉伯语

阿拉伯语 土耳其语

土耳其语

+(86)-133 8863 9264

+(86)-133 8863 9264