Industry knowledge

What is Aluminum Rivet Nuts?

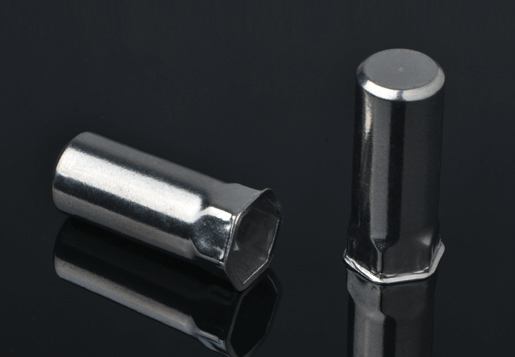

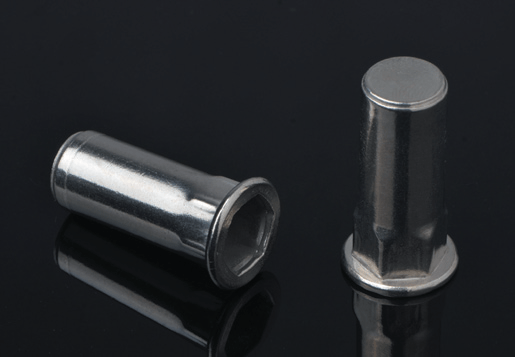

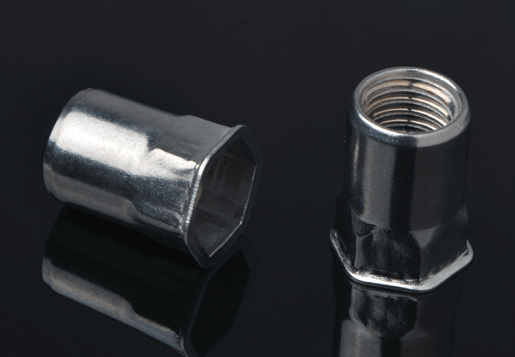

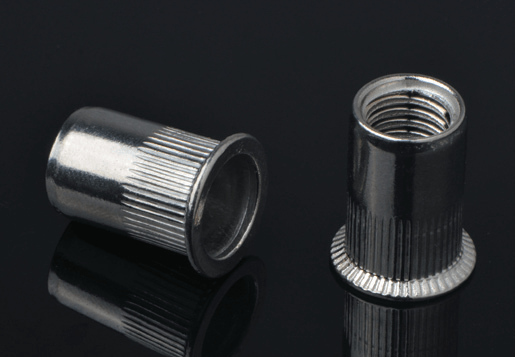

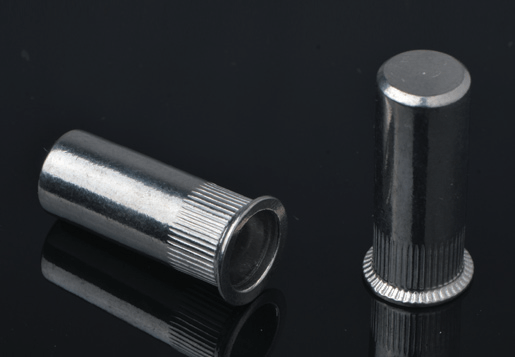

Aluminum rivet nuts, also known as aluminum threaded inserts or aluminum blind rivet nuts, are fasteners used to create a threaded connection in thin materials. They are commonly used in applications where a strong, reliable threaded connection is required but welding or tapping is not feasible or practical.

Aluminum rivet nuts are typically made from aluminum alloy, which provides good strength and corrosion resistance while being lightweight. They consist of a cylindrical body with a threaded hole and flanges on either end. The body is designed to be inserted into a pre-drilled hole in the material, and a specialized tool is used to compress the flanges, deforming the body and creating a secure grip.

The main advantage of aluminum rivet nuts is their ability to provide a strong and durable threaded connection in thin materials, such as sheet metal or plastic, without the need for access to the backside of the material. They can be installed quickly and easily, making them suitable for various applications, including automotive, aerospace, electronics, and furniture assembly.

Aluminum rivet nuts come in different sizes and thread types to accommodate various bolt sizes and applications. They can be used with different installation methods, such as manual tools, pneumatic tools, or automated systems, depending on the specific requirements of the project.

Overall, aluminum rivet nuts offer a reliable and versatile solution for creating threaded connections in thin materials, providing increased efficiency and convenience in various industries.

What are the benefits of Aluminum Rivet Nuts?

Aluminum rivet nuts offer several benefits that make them a popular choice for fastening applications. Here are some of the key advantages:

Lightweight: Aluminum is a lightweight material, making aluminum rivet nuts ideal for applications where weight reduction is important. This is particularly advantageous in industries such as automotive and aerospace, where every ounce of weight savings can contribute to fuel efficiency or payload capacity.

Corrosion resistance: Aluminum rivet nuts are resistant to corrosion, particularly when they are made from aluminum alloys that are specifically designed to enhance corrosion resistance. This makes them suitable for use in environments where exposure to moisture or other corrosive elements is a concern.

Versatility: Aluminum rivet nuts are available in a wide range of sizes and thread types, allowing for compatibility with different bolt sizes and applications. This versatility makes them suitable for a variety of industries and applications, including automotive, electronics, furniture, and more.

Strong and secure connection: When properly installed, aluminum rivet nuts create a strong and reliable threaded connection. They provide excellent resistance to vibration and loosening, ensuring that the fastened components remain securely in place.

Easy installation:

Aluminum rivet nuts can be installed quickly and easily, requiring only access to one side of the material. The installation process typically involves using a specialized tool to compress the flanges and deform the body, creating a secure grip. This simplicity and efficiency make aluminum rivet nuts a convenient choice for assembly operations.

Cost-effective: Aluminum rivet nuts are generally cost-effective compared to other fastening methods, such as welding or tapping. They eliminate the need for additional equipment or complex processes, resulting in time and cost savings during installation.

Removability: Unlike permanent fastening methods like welding, aluminum rivet nuts can be easily removed if necessary. This allows for disassembly and repair or replacement of components without damaging the surrounding material.

Overall, the benefits of aluminum rivet nuts include their lightweight nature, corrosion resistance, versatility, strong connection, ease of installation, cost-effectiveness, and removability. These advantages make them a popular choice for numerous applications across various industries.

EN

EN  英语

英语 俄语

俄语 韩语

韩语 阿拉伯语

阿拉伯语 土耳其语

土耳其语

+(86)-133 8863 9264

+(86)-133 8863 9264