STEADY manufactures over a thousands different types of blind rivet nut in steel,aluminium and stainless steel,thread size from M3-M16 in metric and UNC #6-32 to UNC 1/2-13 in inch. High advantage in stainless steel blind rivets both for open and sealed type, mutigrip,monobolt and other structural rivets. As China Metric Fine Thread Hex Nuts Manufacturers and Metric Fine Thread Hex Nuts Factory, we focus on "one stop shopping" and with advantage of large production capacity , consistent quality, competitive prices, punctual delivery and goods serverices before and after sales, STEADY has become one of the leading blind fasteners manufacuture & supplier in Asia.

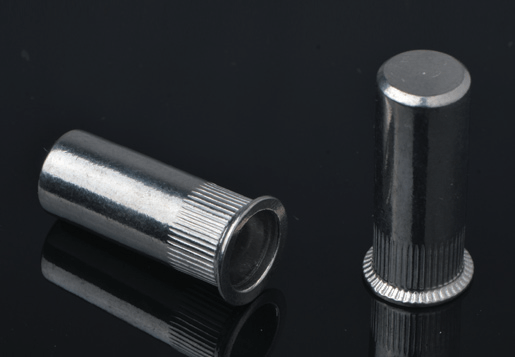

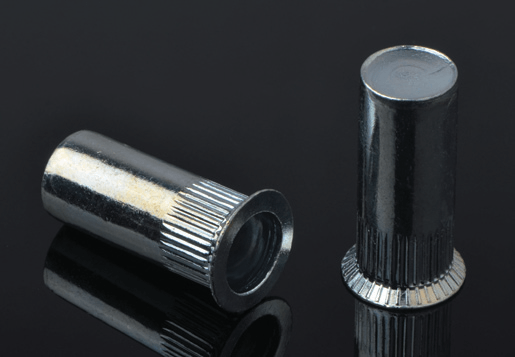

Metric Fine Thread Hex Nuts Manufacturers

-- Steady & Reliable Manufacturer --

Introduction

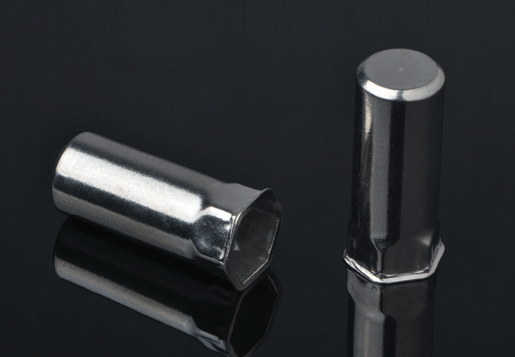

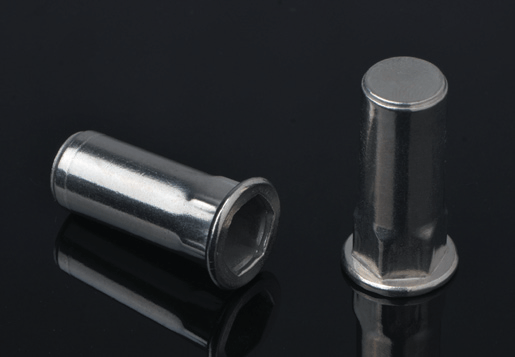

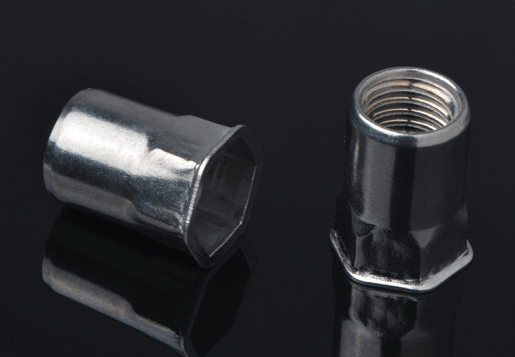

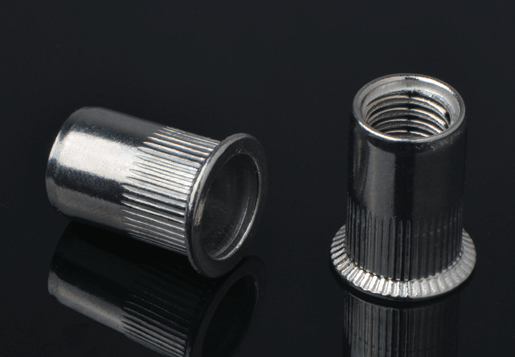

Metric Fine Thread Hex Nuts are utilized in applications requiring precise adjustment, superior locking ability against vibration, and maximum strength in thin-walled sections. Unlike coarse thread (standard) nuts, fine threads have more threads per unit length, resulting in a larger stress area, making the joint stronger and less prone to loosening. They are commonly found in the highly regulated automotive, aerospace, and precision machinery sectors.

Related products

Specification

| Thread Pitch |

Fine Pitch (e.g., M10 x 1.25, M12 x 1.5) |

| Standard |

ISO 8673 |

| Material Options |

Carbon Steel (Class 8, 10), Stainless Steel (A2, A4) |

| Key Advantage |

Higher Stress Area, Finer Adjustment |

| Compatibility |

Requires a matching fine thread bolt or screw |

Applications

-

Precision Machine Tools: Used for fine adjustment on slides, gears, and tool mounts.

-

Automotive Engine Components: Where extreme vibration resistance and high clamp load are needed in compact spaces.

-

Hydraulic and Fluid Power: Providing high pressure-holding capacity in port connections.

-

Gauges and Instrumentation: Used for micro-adjustments and critical locking on measuring equipment.

Advantages

-

Increased Holding Power: The increased number of threads in engagement distributes the load better, making the joint stronger.

-

Better Sealing: Finer thread pitch minimizes the spiral leakage path for gasses and fluids.

-

Finer Adjustment: A smaller angle of rotation is required per linear movement, allowing for more precise positioning.

-

Reduced Loosening: More resistant to dynamic vibration forces compared to coarse thread.

EN

EN  English

English русский

русский 한국어

한국어 عربى

عربى Türk

Türk