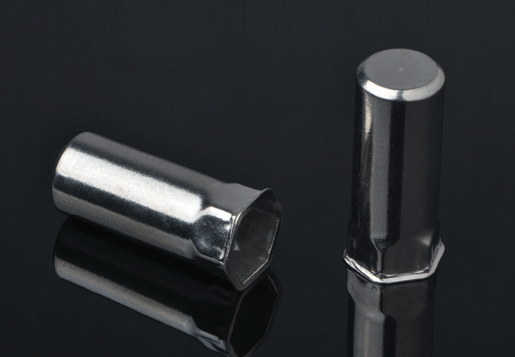

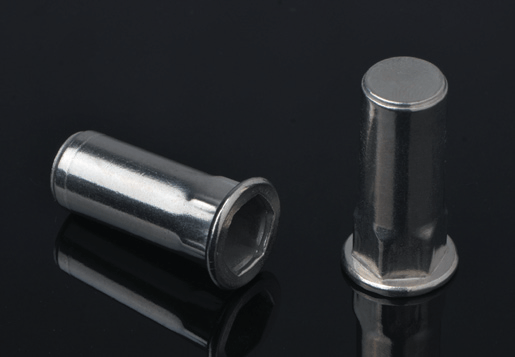

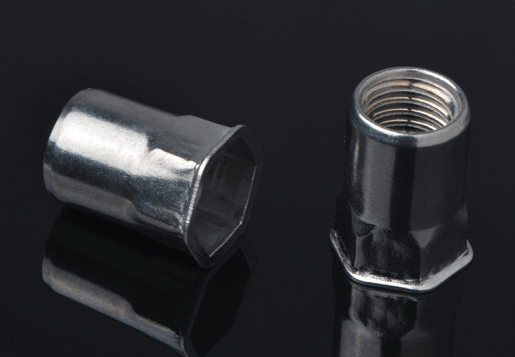

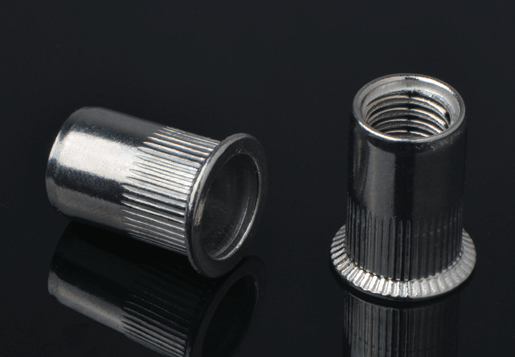

STEADY manufactures over a thousands different types of blind rivet nut in steel,aluminium and stainless steel,thread size from M3-M16 in metric and UNC #6-32 to UNC 1/2-13 in inch. High advantage in stainless steel blind rivets both for open and sealed type, mutigrip,monobolt and other structural rivets. As China Heavy Duty Lifting Eye Bolts Manufacturers and Heavy Duty Lifting Eye Bolts Factory, we focus on "one stop shopping" and with advantage of large production capacity , consistent quality, competitive prices, punctual delivery and goods serverices before and after sales, STEADY has become one of the leading blind fasteners manufacuture & supplier in Asia.

Heavy Duty Lifting Eye Bolts Manufacturers

-- Steady & Reliable Manufacturer --

Introduction

Heavy Duty Lifting Eye Bolts are specialized fasteners designed to create a secure, temporary, or permanent attachment point for lifting equipment (like hooks or slings). These bolts feature a ring or 'eye' at one end and a fully or partially threaded shank at the other. Crucially, lifting eye bolts must be rated for working load limits (WLL) and comply with standards like DIN 580 to ensure maximum safety and prevent failure during hoisting operations in industrial, construction, and marine environments.

Related products

Specification

| Standard |

DIN 580 (General Lifting), DIN 582 (Lifting Nut) |

| Material |

Forged Carbon Steel, Stainless Steel (304, 316) |

| Key Rating |

Working Load Limit (WLL) clearly marked |

| Safety Factor |

Typically 4:1 (against ultimate failure) |

| Recommended Use |

In-line tension only (DIN 580) |

Applications

-

Heavy Machinery Relocation: Providing attachment points for lifting engines, casings, and large tools.

-

Construction Site Lifting: Hoisting prefabricated concrete sections or steel beams.

-

Marine and Offshore: Securing mooring lines or lifting equipment on decks.

-

Industrial Maintenance: Used for periodic removal of large pumps, motors, and gearbox lids.

Advantages

-

Safety Certified: WLL ratings ensure compliance with lifting standards and regulations.

-

Forged Strength: Manufactured through forging to align the material grain flow with the stress, maximizing load capacity.

-

Permanent or Temporary Use: Can be threaded in and out easily for periodic maintenance lifting.

-

Full Traceability: Supplied with certificates of conformity and load testing reports.

EN

EN  English

English русский

русский 한국어

한국어 عربى

عربى Türk

Türk