STEADY manufactures over a thousands different types of blind rivet nut in steel,aluminium and stainless steel,thread size from M3-M16 in metric and UNC #6-32 to UNC 1/2-13 in inch. High advantage in stainless steel blind rivets both for open and sealed type, mutigrip,monobolt and other structural rivets. As China Square Head Set Screws Manufacturers and Square Head Set Screws Factory, we focus on "one stop shopping" and with advantage of large production capacity , consistent quality, competitive prices, punctual delivery and goods serverices before and after sales, STEADY has become one of the leading blind fasteners manufacuture & supplier in Asia.

Square Head Set Screws Manufacturers

-- Steady & Reliable Manufacturer --

Introduction

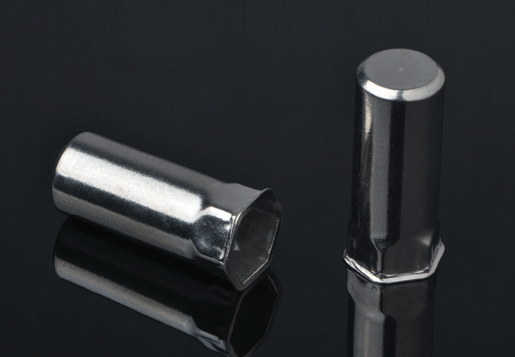

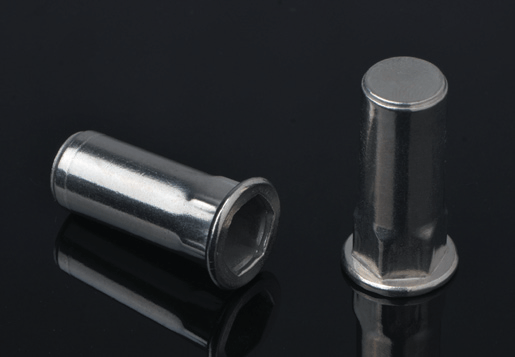

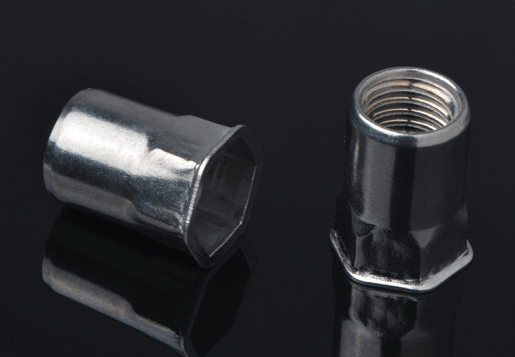

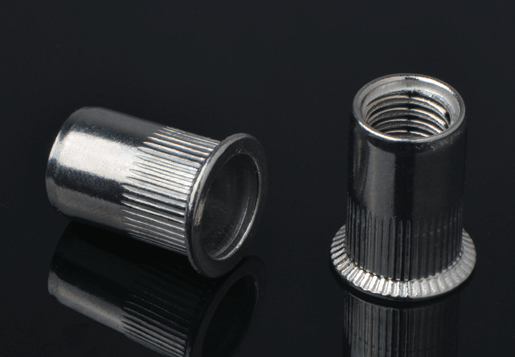

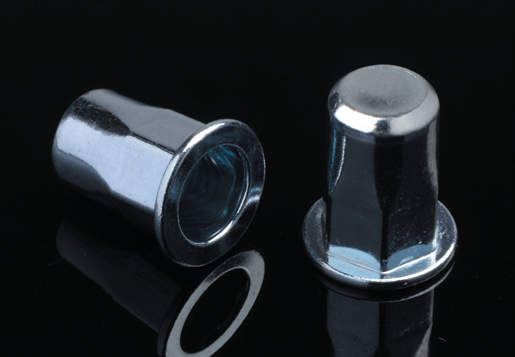

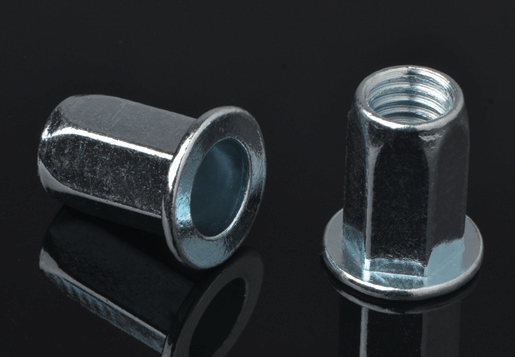

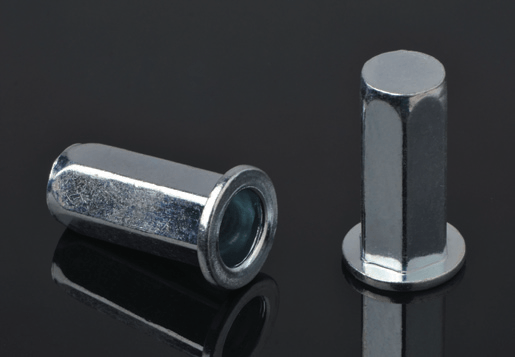

Square Head Set Screws, or often simply called "set screws," are fasteners used to secure a component relative to another by applying clamping force through the screw tip. The square head provides a large surface area for tightening with a wrench, allowing high torque for secure positioning. Unlike common socket set screws, the external head makes them ideal for manual adjustment in heavy machinery and older equipment standards where robustness is prioritized over flush design.

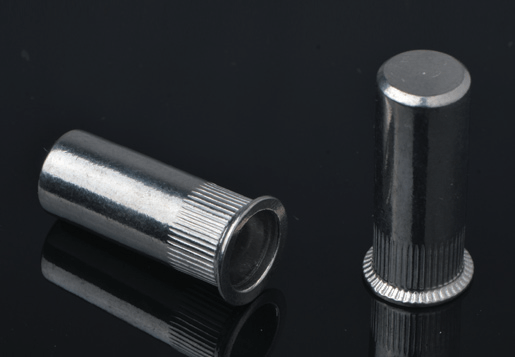

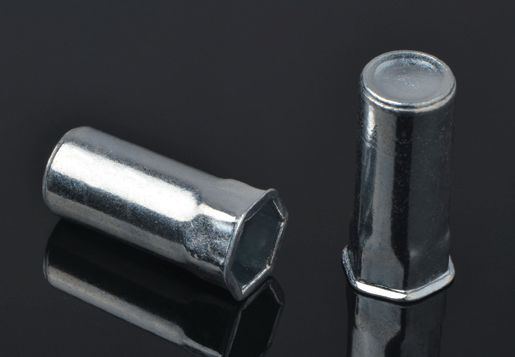

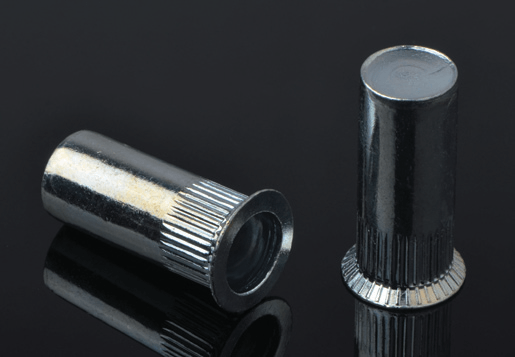

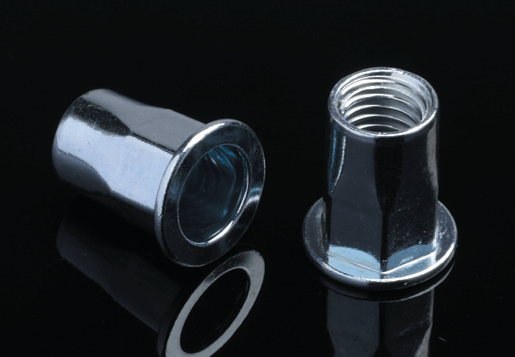

Related products

Specification

| Head Style |

External Square Head |

| Tip Type |

Cup Point, Cone Point, Flat Point |

| Standard |

ASME B18.6.2, DIN 478 |

| Material |

Alloy Steel, Stainless Steel |

| Key Feature |

High Torque Capability |

Applications

-

Heavy Machinery and Equipment: Used for adjusting and locking mechanical parts.

-

Pulleys and Gears: Securing these components onto shafts to prevent rotation.

-

Industrial Jig and Fixtures: Providing adjustable, high-force holding points in manufacturing tools.

-

Pipe Clamps and Collars: Used to fix position along a pipe or rod.

Advantages

-

Manual Adjustment: The external head allows for easy, quick adjustment and locking using standard wrenches.

-

Maximum Tightening Torque: The large square head transfers significantly more torque than internal drive set screws.

-

Durable Tip Selection: A variety of tip points are available to suit different application needs (e.g., cup point for semi-permanent setting, flat point for positioning).

-

Robust Design: Preferred in dirty or high-wear environments where internal drives might clog.

EN

EN  English

English русский

русский 한국어

한국어 عربى

عربى Türk

Türk