Industry knowledge

What is Stainless Steel Rivet Nuts?

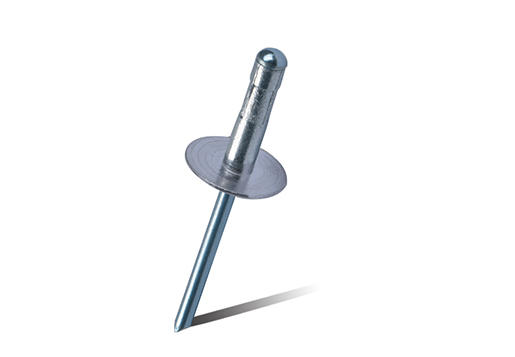

Stainless steel rivet nuts, also known as threaded inserts or rivet nut inserts, are fasteners used to create a threaded connection in materials where it may be difficult or impractical to create threads directly. They are commonly used in applications where strong, reliable, and durable fastening solutions are required.

The rivet nut is a cylindrical, hollow metal insert with a threaded interior and a flanged head. It typically has a knurled or ribbed outer surface to provide enhanced grip when installed. The material used is stainless steel, which offers excellent corrosion resistance and strength, making it suitable for various environments and applications.

To install a

stainless steel rivet nut, a hole is drilled or punched into the material where the nut will be inserted. The rivet nut is then placed into the hole, and a specialized tool, such as a rivet nut setter or a pneumatic/hydraulic tool, is used to compress the flanged head of the rivet nut. This causes the body of the rivet nut to expand and grip the material tightly, creating a secure and threaded connection.

Stainless steel rivet nuts are commonly used in industries such as automotive, aerospace, electronics, furniture, and construction. They provide a reliable and efficient method for adding threads to thin or brittle materials, such as sheet metal, plastic, composites, or fiberglass, where traditional threaded fasteners cannot be used effectively.

Why Choose Stainless Steel Rivet Nuts?

There are several reasons why one might choose stainless steel rivet nuts for their applications:

Corrosion resistance: Stainless steel is known for its excellent corrosion resistance properties. It can withstand exposure to moisture, chemicals, and other harsh environments without rusting or corroding. This makes stainless steel rivet nuts ideal for outdoor, marine, or corrosive environments.

Strength and durability: Stainless steel rivet nuts offer high strength and durability, making them suitable for applications that require reliable and long-lasting fastening solutions. They can handle heavy loads, vibration, and repeated use without compromising their performance.

Aesthetics: Stainless steel has a sleek and attractive appearance. If the rivet nuts are visible in the application, such as in furniture or architectural components, stainless steel rivet nuts can provide an appealing and professional look.

Compatibility:

Stainless steel rivet nuts can be used with a wide range of materials, including metals, plastics, composites, and fiberglass. This versatility allows for flexible and adaptable applications across different industries.

Easy installation: Installing stainless steel rivet nuts is relatively simple and can be done using specialized tools or equipment. They require minimal preparation and can be installed quickly, saving time and effort during assembly.

Threaded versatility: Once installed, stainless steel rivet nuts provide a threaded insert, allowing for easy attachment of screws, bolts, or other threaded fasteners. This facilitates disassembly and reassembly, making them a convenient choice for applications that require frequent maintenance or repairs.

Cost-effective: While stainless steel rivet nuts may have a higher upfront cost compared to other fastening methods, their durability and resistance to corrosion can result in long-term cost savings. They reduce the need for frequent replacements or repairs, leading to lower maintenance and downtime costs.

Overall, stainless steel rivet nuts offer a combination of corrosion resistance, strength, durability, and aesthetic appeal, making them a popular choice for a wide range of applications in various industries.

EN

EN  英语

英语 俄语

俄语 韩语

韩语 阿拉伯语

阿拉伯语 土耳其语

土耳其语

+(86)-133 8863 9264

+(86)-133 8863 9264