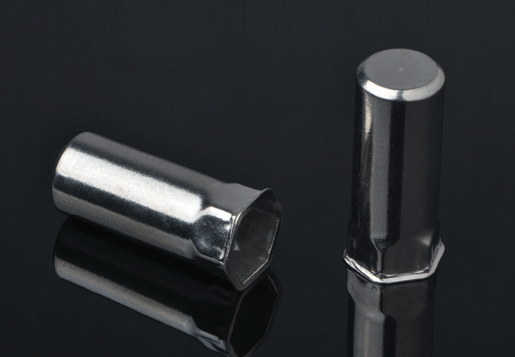

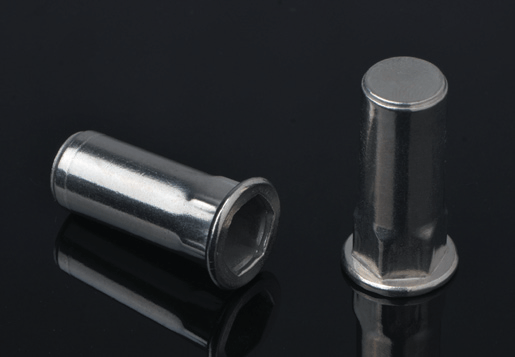

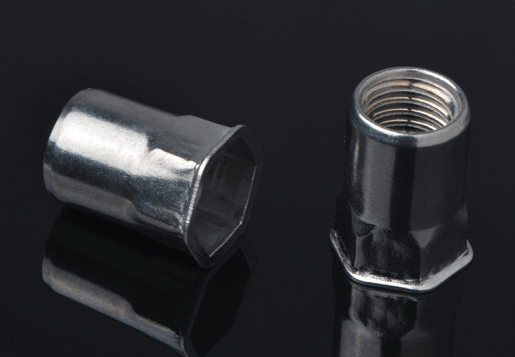

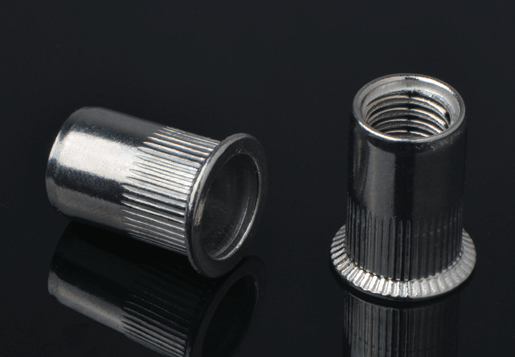

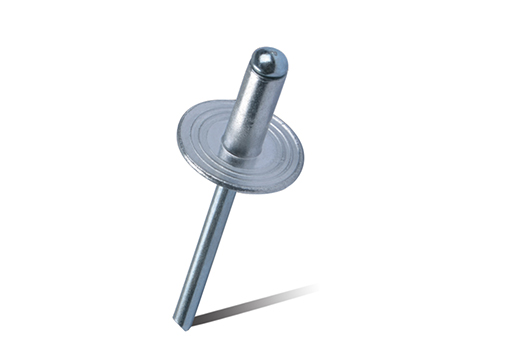

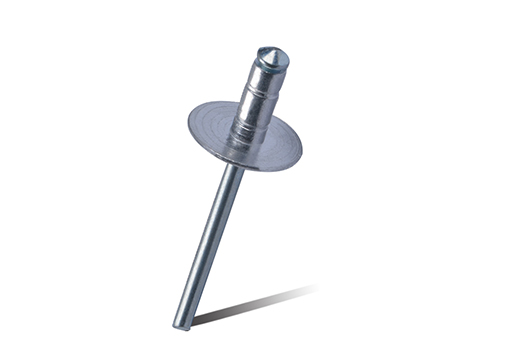

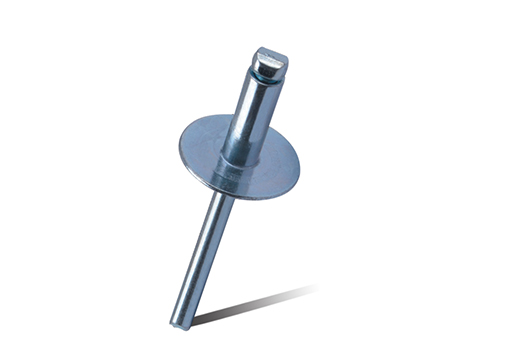

STEADY manufactures over a thousands different types of blind rivet nut in steel,aluminium and stainless steel,thread size from M3-M16 in metric and UNC #6-32 to UNC 1/2-13 in inch. High advantage in stainless steel blind rivets both for open and sealed type, mutigrip,monobolt and other structural rivets. As China Large Diameter Fasteners (Generic) Manufacturers and Large Diameter Fasteners (Generic) Factory, we focus on "one stop shopping" and with advantage of large production capacity , consistent quality, competitive prices, punctual delivery and goods serverices before and after sales, STEADY has become one of the leading blind fasteners manufacuture & supplier in Asia.

Large Diameter Fasteners (Generic) Manufacturers

-- Steady & Reliable Manufacturer --

Introduction

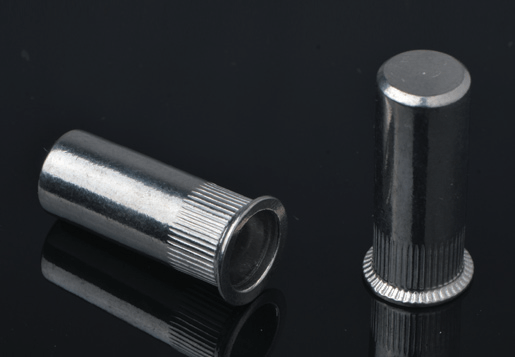

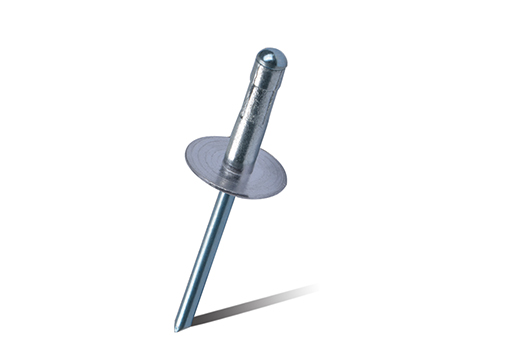

Large Diameter Fasteners are bolts, studs, and nuts with diameters typically exceeding 1 inch (M24 metric) and are designed to handle immense structural loads in heavy engineering projects. These specialized components are mandatory for connecting primary load-bearing structures in bridges, wind turbines, pressure vessels, and large machinery. They require specialized manufacturing processes (hot or cold forging) and rigorous quality control, including non-destructive testing (NDT), to ensure maximum integrity and safety under extreme stress.

Related products

Specification

| Diameter Range |

Over 1聽inch (M24+) |

| Common Grades |

ASTM A193 B7, A490, A354 BD |

| Manufacturing |

Hot Forging, Roll Threading |

| Key Application |

Structural, High Load |

| Required Testing |

Magnetic Particle Inspection (MPI), Ultrasonic Testing (UT) |

Applications

-

Wind Turbine Foundations: Anchoring the tower base to the concrete platform.

-

Oil & Gas Pressure Vessels: Bolting large flanges on reactors and storage tanks.

-

Bridge Construction: Connecting massive steel girders and suspension components.

-

Hydraulic Press and Forge Equipment: Securing the primary frame and tie rods.

Advantages

-

Exceptional Load Capacity: Designed to withstand extreme tensile and shear forces far beyond standard fasteners.

-

Material Integrity: Hot forging ensures optimal material grain flow, maximizing strength and fatigue life.

-

Deep Engagement: Large threads are less susceptible to damage and provide excellent thread contact area.

-

Full Traceability: Mandatory material certificates and NDT reports ensure complete project compliance.

EN

EN  English

English русский

русский 한국어

한국어 عربى

عربى Türk

Türk