STEADY manufactures over a thousands different types of blind rivet nut in steel,aluminium and stainless steel,thread size from M3-M16 in metric and UNC #6-32 to UNC 1/2-13 in inch. High advantage in stainless steel blind rivets both for open and sealed type, mutigrip,monobolt and other structural rivets. As China Custom Cold Forged Fasteners Manufacturers and Custom Cold Forged Fasteners Factory, we focus on "one stop shopping" and with advantage of large production capacity , consistent quality, competitive prices, punctual delivery and goods serverices before and after sales, STEADY has become one of the leading blind fasteners manufacuture & supplier in Asia.

Custom Cold Forged Fasteners Manufacturers

-- Steady & Reliable Manufacturer --

Introduction

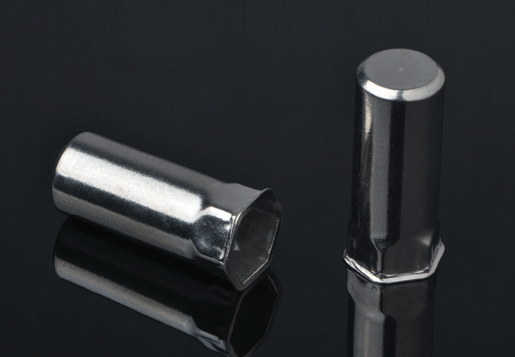

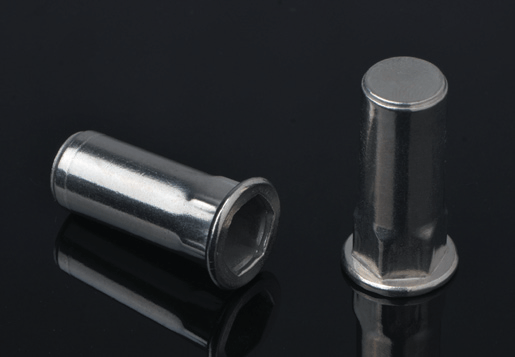

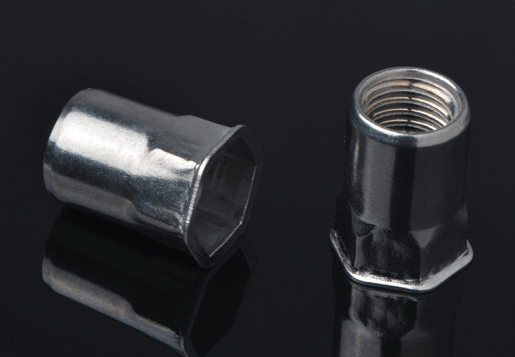

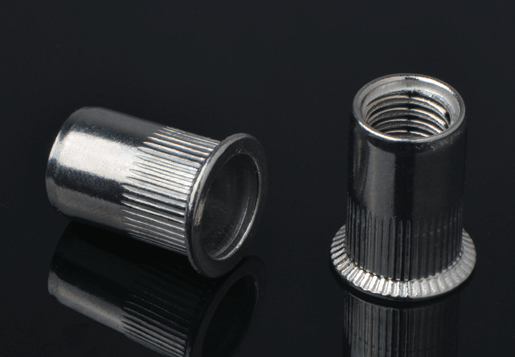

Our custom cold forging service specializes in manufacturing non-standard and complex geometry fasteners from pre-heated billets. Cold forging is a process that deforms metal at room temperature, dramatically improving the material's grain structure and mechanical properties, resulting in fasteners with superior tensile strength, fatigue resistance, and dimensional accuracy compared to machining alone. This is the optimal process for high-volume, high-performance special bolts and screws.

Related products

Specification

| Process |

Multi-Station Cold Heading / Forging |

| Material Suitability |

Carbon, Alloy, Stainless Steel, Brass, Aluminum |

| Diameter Range |

Typically M3 to M24 (up to 1 inch) |

| Key Advantage |

Enhanced Material Strength & No Material Loss |

| Customization |

Unique Head Shapes, Integral Washers, Special Shanks |

Applications

-

Automotive Engine Bolts: Requiring high fatigue life and complex shoulder geometry.

-

Aerospace Components (Non-critical): Used where superior mechanical properties are needed at a competitive cost.

-

Appliance/Electronics OEMs: Manufacturing high volumes of proprietary, security, or non-standard fasteners.

-

Special Machinery: Creating integrated fastener/pin components in one piece.

Advantages

-

Superior Strength: Cold work hardening increases the mechanical properties of the final product.

-

Cost Efficiency (Volume): Highly economical for medium to large production runs (50k+ pieces).

-

Grain Flow Optimization: The material grain follows the contour of the head, minimizing stress points and increasing fatigue resistance.

-

Zero Waste: Near-net-shape forming means minimal material loss compared to machining.

EN

EN  English

English русский

русский 한국어

한국어 عربى

عربى Türk

Türk