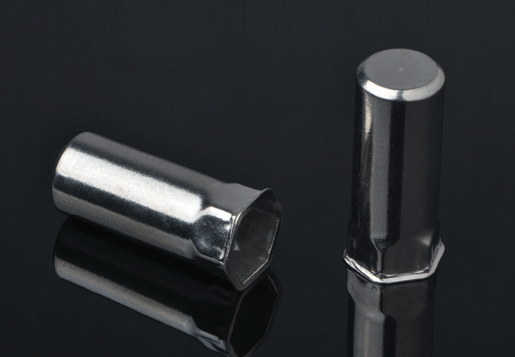

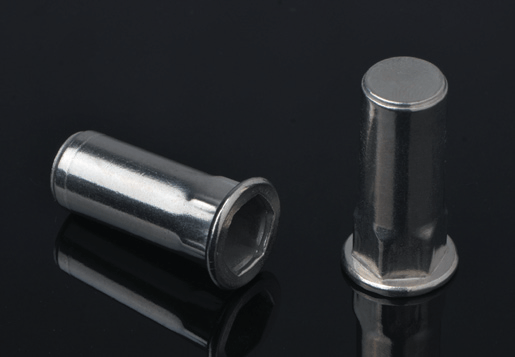

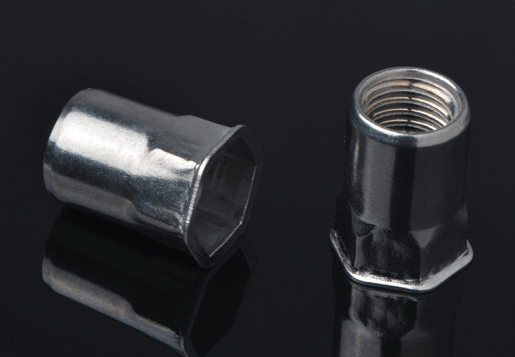

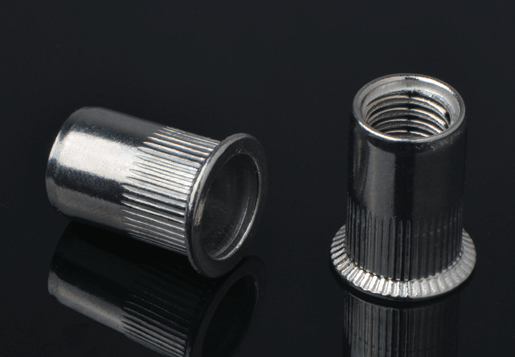

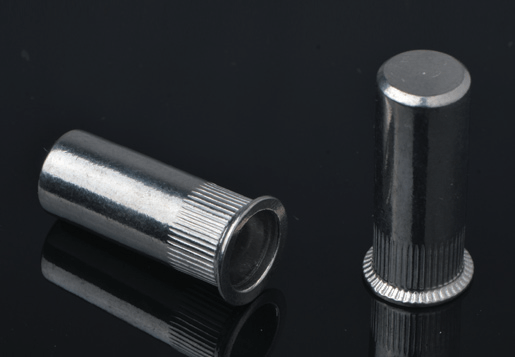

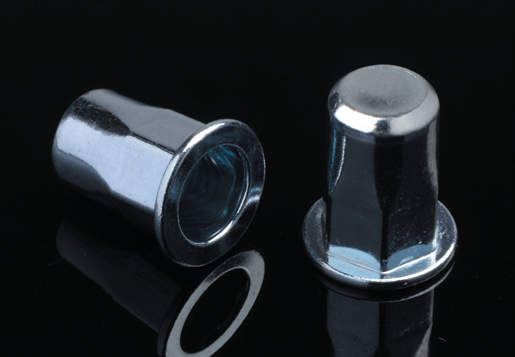

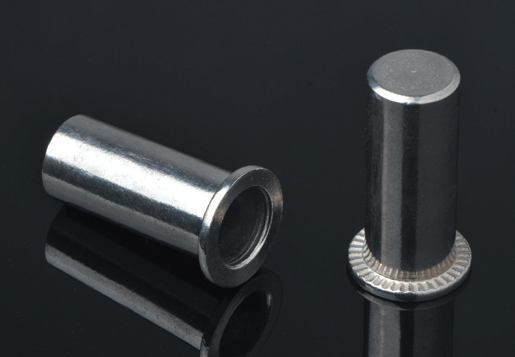

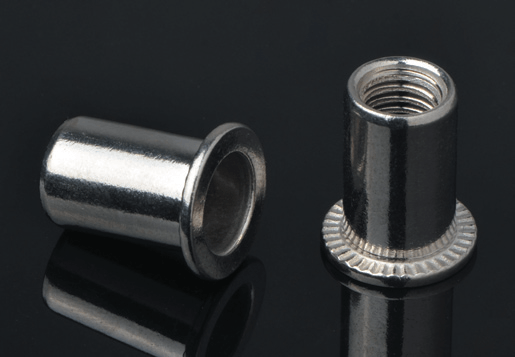

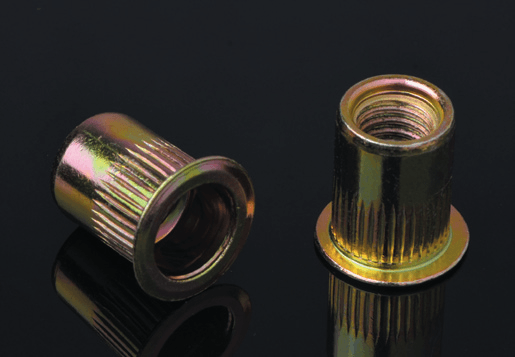

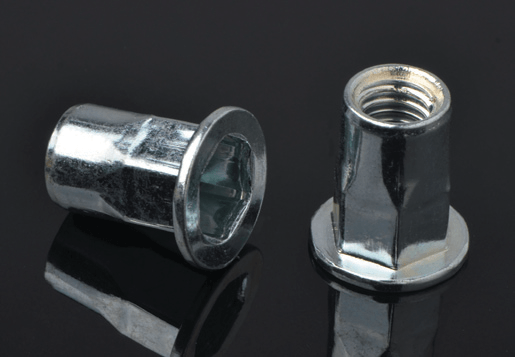

STEADY manufactures over a thousands different types of blind rivet nut in steel,aluminium and stainless steel,thread size from M3-M16 in metric and UNC #6-32 to UNC 1/2-13 in inch. High advantage in stainless steel blind rivets both for open and sealed type, mutigrip,monobolt and other structural rivets. As China ASTM F436 Hardened Washers Manufacturers and ASTM F436 Hardened Washers Factory, we focus on "one stop shopping" and with advantage of large production capacity , consistent quality, competitive prices, punctual delivery and goods serverices before and after sales, STEADY has become one of the leading blind fasteners manufacuture & supplier in Asia.

ASTM F436 Hardened Washers Manufacturers

-- Steady & Reliable Manufacturer --

Introduction

ASTM F436 hardened washers are mandatory for use with high-strength structural bolts, specifically ASTM A325 and A490, as well as galvanized fasteners. These washers are heat-treated to a high hardness level, ensuring they can withstand the massive compressive forces exerted by tensioned structural bolts. They prevent damage to the mating surface of the structural steel and distribute the load evenly, which is crucial for the integrity of friction-type connections.

Related products

Specification

| Standard |

ASTM F436 / F436M |

| Hardness Range |

38 to 45 HRC (Rockwell C Scale) |

| Compatibility |

ASTM A325, A490 Bolts |

| Configuration |

Circular, Beveled (for sloped surfaces) |

| Finishes |

Plain, Hot Dip Galvanized, Mechanically Galvanized |

Applications

-

Structural Steel Construction: Essential for connecting main load-bearing members in buildings and bridges.

-

High-Strength Bolted Joints: Used whenever an A325 or A490 bolt is tensioned.

-

Heavy Equipment Repair: Used in joints requiring high clamp load and resistance to loosening.

-

Anchor Bolt Assemblies: Providing a robust bearing surface for anchor bolt nuts.

Advantages

-

Load Distribution: Spreads the high clamping force over a wider area, preventing distortion of the connected material.

-

Prevents Galling: Acts as a smooth surface for the nut to turn against, ensuring correct torque application.

-

Required by Code: Mandatory for specific structural steel connections worldwide (AISC, Eurocode).

-

Dimensional Consistency: Precision stamping ensures accurate dimensions, vital for proper friction-type joints.

EN

EN  English

English русский

русский 한국어

한국어 عربى

عربى Türk

Türk