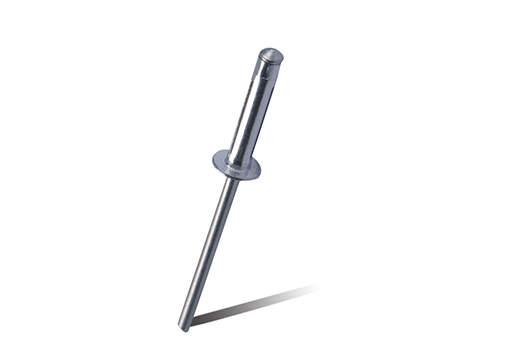

STEADY manufactures over a thousands different types of blind rivet nut in steel,aluminium and stainless steel,thread size from M3-M16 in metric and UNC #6-32 to UNC 1/2-13 in inch. High advantage in stainless steel blind rivets both for open and sealed type, mutigrip,monobolt and other structural rivets. As China All-Metal Prevailing Torque Nuts Manufacturers and All-Metal Prevailing Torque Nuts Factory, we focus on "one stop shopping" and with advantage of large production capacity , consistent quality, competitive prices, punctual delivery and goods serverices before and after sales, STEADY has become one of the leading blind fasteners manufacuture & supplier in Asia.

All-Metal Prevailing Torque Nuts Manufacturers

-- Steady & Reliable Manufacturer --

Introduction

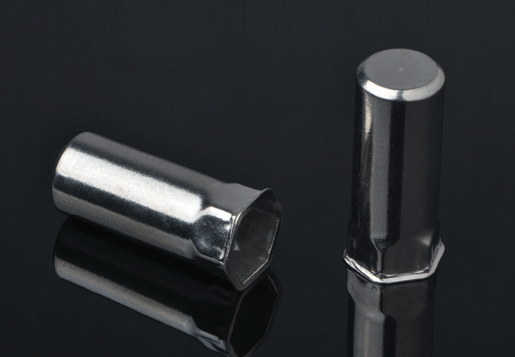

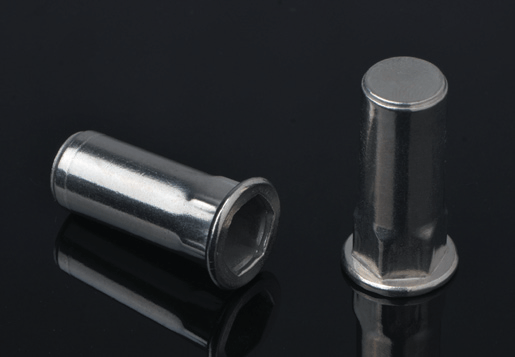

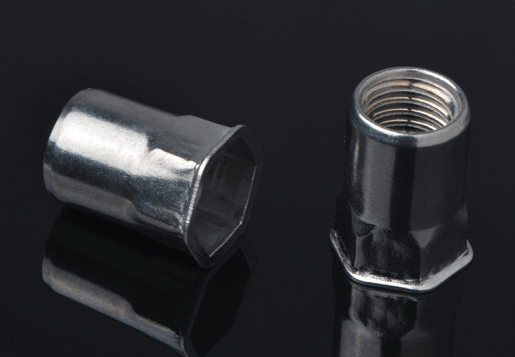

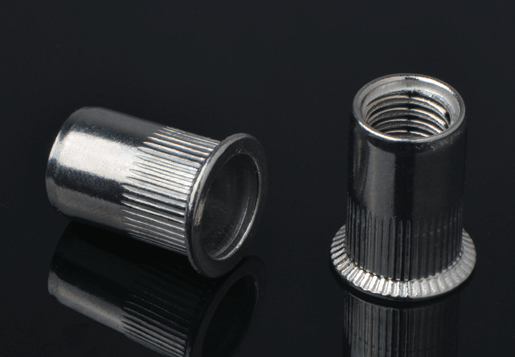

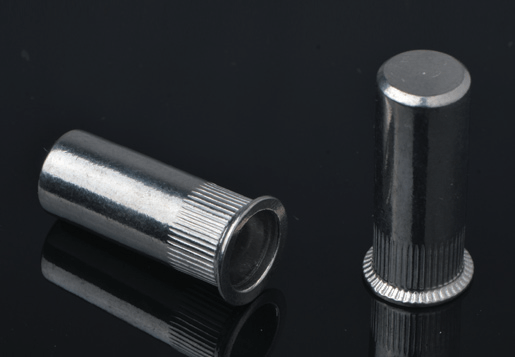

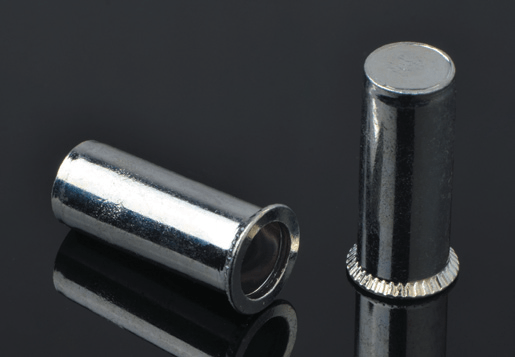

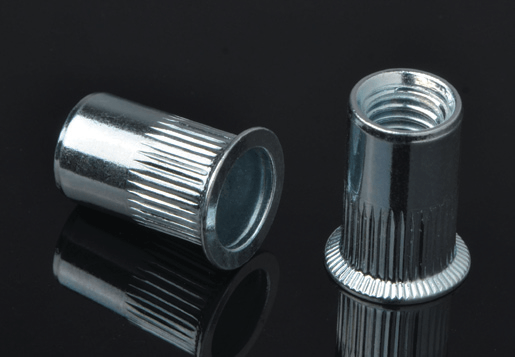

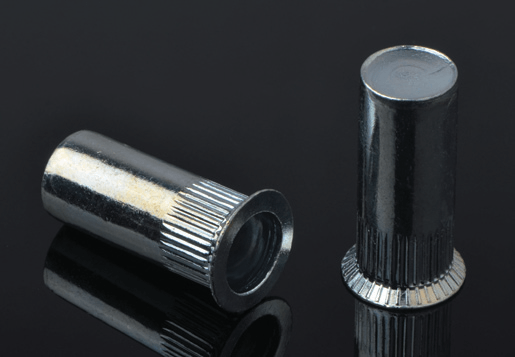

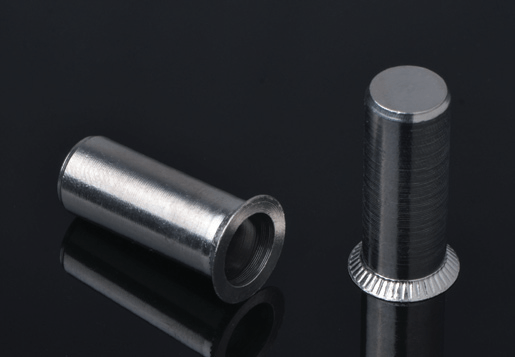

All-Metal Prevailing Torque Nuts are high-performance self-locking fasteners designed to resist loosening caused by severe vibration and extreme thermal cycles. Unlike Nyloc nuts, these nuts have no plastic inserts and achieve their locking action through an engineered deformation (usually an elliptical top or slotted collar) that creates friction on the mating bolt threads. This all-metal construction makes them mandatory for high-temperature applications (up to 600鈭楩 or higher) where polymer inserts would melt or degrade, such as exhaust systems, furnaces, and engine bays.

Related products

Specification

| Locking Mechanism |

All-Metal Frictional Deformation |

| Common Styles |

Stover, Marsden, Reversible (Center-Lock) |

| Material Options |

Carbon Steel (Grade C), Alloy Steel, High-Temp Stainless |

| Temperature Range |

High-Temp (e.g., up to 600鈭楩) |

| Standard |

DIN 980 V, IFI-100/107 |

Applications

-

Automotive Exhaust Systems: Used near the engine and catalytic converter where temperatures are high.

-

Industrial Furnaces and Ovens: Securing internal components in high-heat environments.

-

Aerospace and Aircraft: Used in engine mounts and airframe sections prone to thermal cycling.

-

Vibrating Machinery: Critical industrial equipment like rock crushers or large compressors.

Advantages

-

High Heat Tolerance: Performs reliably at temperatures far exceeding the limits of plastic insert nuts.

-

Excellent Reusability: Maintains a higher percentage of original prevailing torque after multiple installation cycles than nylon-based nuts.

-

Strong Vibration Lock: Provides dependable frictional resistance across the entire length of engagement.

-

Uniform Height: Many designs maintain the same overall dimensions as a standard hex nut.

EN

EN  English

English русский

русский 한국어

한국어 عربى

عربى Türk

Türk